Services and products

Logiserv Group offers comprehensive manufacturing services including design, quotation, implementation and delivery of components. We have a versatile machinery park, so our services meet the requirements of companies representing various industries.

Quotation in 48 hours

Thanks to the latest technological solutions, we realise diverse – including individual, out-of-the-box projects. Using state-of-the-art laser devices and machine tools from TRUMPF and BLM, as well as Bullmer cutting systems and Veit laminating machines, we guarantee excellent precision in the production of our components. We carry out painting services on a state-of-the-art Rippert paint line, and the above-average efficiency of the sewing and fabric cutting processes is ensured by an automatic warehouse integrated with a single- and multi-layer cutter.

Transport

As Logiserv Group, we are rapidly growing in the logistics- TSL industry. Since 2019. we have been providing international transport services within the European Union countries. During this time we have specialized comprehensively in freight logistics.

Production of polyurethane foam parts

The service includes the production of polyurethane foam products in both standard and higher flame retardant grades, ranging in weight from 250 g to 5 kg. We carry out the order using robots for the application of release agent and mould casting, thus guaranteeing that the manufactured parts are 100% reproducible and correct. We offer a service with short lead times, thanks to the high efficiency of the production of smaller parts.

Sewing and cutting of fabrics

We use the latest technology to make the fabric processing process very efficient - ensuring maximum utilisation of the fabric entrusted to us and reducing waste to a minimum. Thanks to the maximum cutting thickness of up to 80 mm, the process allows multiple layers of fabric to be processed simultaneously, which makes it possible to complete serial orders quickly. We provide the highest quality fabric processing with a cutting accuracy of:

+/- 0.1 mm. The service includes cutting technical textiles, composites or fabric sheets. We have machines with working widths from 1400 mm to 5000 mm, among others.

Powder coating

Powder coatingThe painting service for metal parts with dimensions up to 4000 x 1600 mm, up to a maximum load of 200 kg. The high quality of the painting process involves a multi-stage,

wet chemical process followed by powder coating. Thanks to the high performance of the paint line we use, which provides painting at a speed of 6m/s, we offer short turnaround times. The innovative powder application system allows us to optimise our execution costs, making our service offer very favourable.

Automatic welding

A welding service with perfect repeatability of each weld, guaranteed by the use of welding robots. We use TIG technology, which makes it possible to join different types of metal with precision and with the highest quality. We use equipment equipped with a component detection system that eliminates the risk of errors during loading, and a multi-instrument base with four positioners allows us to minimise set-up times to shorten the execution process.

Bending of wire, bars and flat bars

Wire bending service with diameters between 3 mm and 12 mm, as well as bending rods, flat bars or resistors. Almost any shape is possible with the nine-axis bending option. Our state-of-the-art, fully automated material processing enables us to complete orders within unbeatable lead times.

Profile bending

Profile bending service from 15 to 50 mm. The ability to bend in fourteen axes ensures that almost any shape can be achieved. Bending to the right, to the left in a fixed, variable or multi-radius process. The ability to fit eight tools simultaneously and to work at a maximum infeed speed of 1,000 mm/s allow us to carry out the process extremely efficiently - ensuring short lead times.

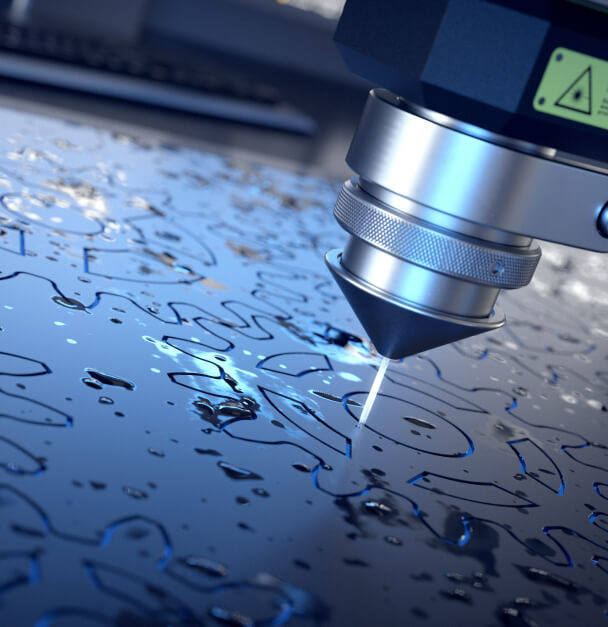

Laser cutting of tubes and profiles

Laser cutting service for tubes with circular cross-sections from 12 to 240 mm in diameter. We offer cutting of both open and closed profiles for a wide range of thicknesses, shapes and geometries. The service includes both 2D and 3D cutting. Thanks to the possibility of double loading and unloading, production is carried out without downtime associated with changeovers, so lead times are reduced to a minimum.

Sheet metal bending

A sheet metal bending service with excellent workmanship right from the first detail. The extremely efficient machining process, as well as the minimal set-up time provided by the TRUMPF machine designed for this service, make a positive contribution to the overall turnaround time.

3D laser cutting

Extremely precise laser cutting of sheet metal at a speed of 265 m / minute. High-quality workpieces are guaranteed, even with very complex contours. The smallest programmable step is 0.001 mm, the positioning deviation is + 0.10 mm and the average positioning deviation is + 0.03 mm.

Automatic rotary cutting

Sheet bending service with a maximum thickness of 4 mm and a bending length of up to 3 metres. An extremely efficient, automated process allows us to complete the job in a rapid manner. Plate clamping or repositioning is carried out at a speed of 3,000 mm/s. The ToolMaster Bend system, with which our machines are equipped, prevents set-up errors, reduces set-up time and enables the economic production of individual parts.

Laser cutting of sheet metal

Sheet metal punching service with very high precision provided by laser technology combined with a powerful punching head. Includes laser punching of non-ferrous metals, foiled stainless steel and galvanised sheets up to 8 mm thick. We offer unbeatably fast turnaround times thanks to the machine's high performance, which provides cutting speeds of up to 34 m per minute and the ability to carry out several jobs in parallel at the same time, such as machining parts and trimming.

Translated with www.DeepL.com/Translator (free version)

Wszystkie usługi realizujemy z zachowaniem najwyższej precyzji i krótkich terminów wykonania, które dodatkowo skracamy dzięki własnej logistyce transportowej.

CONTACT

Looking fora professional production

company?

We look forward to working with you!